Custom Direct-To-Film Transfers, or DTF Transfers as commonly known, are cutting-edge printing technology that has revolutionized the world of textile printing. One of the greatest advantages of DTF Transfers is their ability to produce high-quality prints with unmatched color vibrancy and image sharpness. However, like any other technology, the quality of the prints is only as good as the process used to create them. Below are 4 tips for enhancing quality in custom DTF Transfers.

1. Source Quality Transfer Paper

The quality of the transfer paper used significantly impacts the quality of the final print. While several transfer paper brands are available, not all are created equal. To ensure the best results, it is advisable to use high-quality transfer paper designed for DTF printing. This guarantees optimal ink absorption, color transfer, and image sharpness, ultimately improving the print quality.

2. Use High-quality Ink

Apart from the quality of the transfer paper, the type of ink used is also critical in determining the quality of the print. For Custom Direct-To-Film Transfers, it is recommended to use pigment-based ink over dye-based ink. Pigment-based ink is known to produce vibrant colors that do not fade easily and are water-resistant, making them ideal for printing on fabrics.

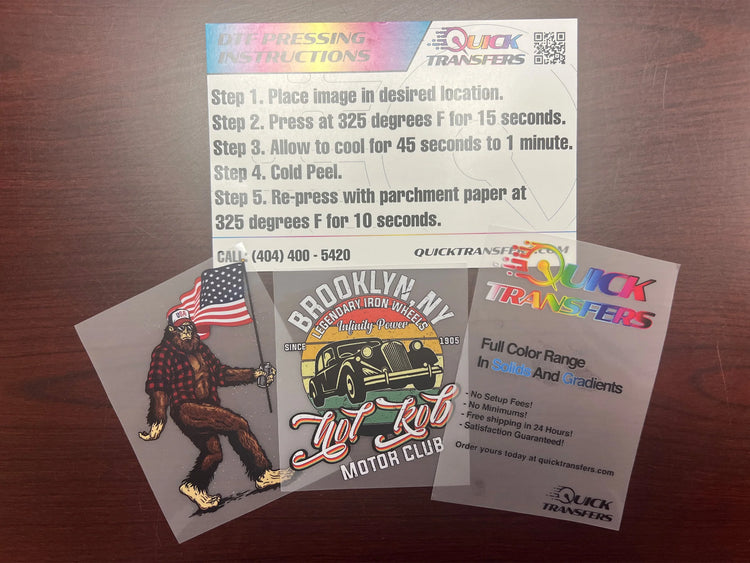

3. Control the Heat Press

Proper control of the heat press is critical in achieving high-quality prints. First, the temperature and pressure settings should be carefully calibrated to match the transfer paper and ink specifications. Secondly, it is essential to apply uniform pressure to ensure that the ink is evenly transferred onto the fabric.

4. Optimize the Image

Finally, optimizing the image before printing is crucial for achieving high-quality prints. This can be done by ensuring the image resolution is high enough, and the colors are accurately represented. Additionally, the image should be properly sized and positioned on the transfer paper to minimize distortion during printing.

In summary, achieving high quality in Custom Direct-to-Film Transfers requires proper control of several variables such as the transfer paper, ink, heat press, and image optimization. Using the tips outlined above, anyone can achieve high-quality prints with unmatched color vibrancy and sharpness. Looking for quick DTF transfers? Visit Quick Transfers at https://quicktransfers.com for all your DTF needs.